16 Basic Knowledge About PLC

1. From the perspective of the composition of PLC, in addition to the CPU, memory and communication interfaces, what other interfaces are directly related to the industrial site? And explain their main functions.

(1) Input interface: accepts the signal from the controlled device, and drives the internal circuit to turn on or off through the photoelectric coupling device and the input circuit.

(2) Output interface: The execution result of the program is output through the photoelectric coupling device and output components (relay, thyristor, transistor) of the output interface to control the on or off of the external load.

2. What parts does the basic unit of PLC consist of? What is the role of each?

(1) CPU: The core component of PLC, commanding PLC to perform various tasks. Such as accepting user programs and data, diagnosing, executing execution programs, etc.;

(2) Memory: stores system and user programs and data;

(3) I/O interface: The connection component between the PLC and the controlled object at the industrial production site, used to receive signals from the controlled equipment and output the execution results of the program;

(4) Communication interface: exchange information with other devices such as monitors and printers through the communication interface;

(5) Power supply.

3. What types of PLC switching output interfaces are there? What are the characteristics of each?

Thyristor output type: Under normal circumstances, it can only carry AC load, has fast response speed and high operating frequency;

Transistor output type: Under normal circumstances, it can only carry DC load, has fast response speed and high operating frequency;

Relay output type: Under normal circumstances, it can carry AC and DC loads, but its response time is long and the action frequency is low.

4. According to the structural type, what are the types of PLC? What are the characteristics of each?

(1) Integral type: The CPU, power supply, and I/O components are all concentrated in one chassis. It has a compact structure and low price. Generally, small PLCs adopt this structure;

(2) Modular type: Divide each part of the PLC into several separate modules. Different modules can be selected as needed to form a system. It has the characteristics of flexible configuration, convenient expansion and maintenance. Generally, medium and large PLCs adopt this structure. Modular PLC consists of a frame or base plate and various modules, which are installed on the sockets of the frame or base plate.

(3) Stacked type: It combines the characteristics of the integral type and the modular type. The CPU, power supply, I/O interface, etc. of the stacked PLC are also independent modules, but they are connected by cables, so that the system not only configures Flexible and compact.

5. What is the scan cycle of PLC? What is it mainly affected by?

The PLC scanning process includes five stages: internal processing, communication services, input processing, program execution, and output processing. The time required for a scan in these five stages is called the scan cycle.

The scan cycle is related to the CPU running speed, PLC hardware configuration and user program length.

6. How does the PLC execute the user program? What stages does the user program execution process include?

The PLC executes the user program in a cyclic scanning manner. The execution process of the user program includes the input sampling stage, the program execution stage and the output refresh stage.

7. What are the advantages of PLC control system compared with relay control system?

(1) In terms of control method: PLC uses program mode to achieve control, which is easy to change or increase control requirements, and PLC has unlimited contacts;

(2) Working mode: PLC adopts serial working mode to improve the anti-interference ability of the system;

(3) In terms of control speed: the contacts of the PLC are actually triggers, and the instruction execution time is at the microsecond level;

(4) Timing and counting: PLC uses semiconductor integrated circuits as timers, and the clock pulse is provided by a crystal oscillator. The delay accuracy is high and the range is wide. PLC has counting functions that relay systems do not have;

(5) Reliability and maintainability: PLC adopts microelectronics technology and has high reliability. Its self-checking function can detect its own faults in time, and its monitoring function facilitates debugging and maintenance.

8. Why does PLC produce output response lag? How to improve I/O response speed?

Because PLC adopts the cyclic scanning mode of centralized sampling and centralized output, the status of the input terminal can only be read in the input sampling phase of each scan cycle, and the execution results of the program are only sent out in the output refresh phase; secondly, the input of the PLC , output delay, user program length, etc. can all cause output response lag.

It is necessary to improve I/O response through various methods such as input sampling and output refreshing, or direct input sampling and output refreshing, as well as interrupt input and output and intelligent I/O interfaces.

Additional resources:7 Types of Automatic Sorting Equipment, Summarized in Place!

A Summary of the Advantages and Disadvantages of Front-Wheel Drive, Rear-Wheel Drive, and Four-Wheel Drive

Which is the Better Transportation Method: Cable Car or Ropeway?

How does a fixed grip chairlift work?

What are the parts of aerial work platform?

Unlocking the Secrets of Radiation Measurement Instruments: How Do They Work?

What are the applications of electric wheel loaders?

9. What types of soft relays are there in the FX0N series PLC?

Input relay, output relay, auxiliary relay, status register, timer, counter, data register.

10. How to choose PLC?

1) Model selection: Several aspects such as structural form, installation method, functional requirements, response speed, reliability requirements, and model uniformity should be considered;

2) Capacity selection: should be considered from two aspects: I/O points and user storage capacity;

3) I/O module selection: including switching and analog I/O module selection, as well as special function module selection;

4) Selection of power modules, programmers and other equipment.

11. Briefly describe the characteristics of PLC’s centralized sampling and centralized output working methods. What are the advantages and disadvantages of using this working method?

Concentrated sampling: Within a scan cycle, the input state is sampled only during the input sampling phase. When entering the program execution phase, the input terminal will be blocked.

Centralized output: In one scan cycle, only during the output refresh stage, the output-related status in the output image register is transferred to the output latch, and the output interface is refreshed. In other stages, the output status is always saved in the output image. in the register. Adopting this working method can improve the anti-interference ability of the system and enhance the reliability of the system, but it will cause a lag in the PLC input/output response.

12. What kind of working method does PLC use? What are its characteristics?

PLC adopts the working methods of centralized sampling, centralized output and cyclic scanning.

Features: Centralized sampling means that within a scan cycle, the PLC samples the input status only during the input sampling phase. When entering the program execution phase, the input terminal will be blocked.

Centralized output means that within a scan cycle, the PLC only transfers the output-related status in the output image register to the output latch during the output refresh phase, refreshes the output interface, and keeps the output status in other phases. in the output image register.

Cyclic scanning means that the PLC needs to perform multiple operations within a scanning cycle. It uses a time-sharing scanning method to execute the operations one by one in sequence, and the operation is repeated over and over again.

13. What are the main parts of an electromagnetic contactor? Briefly describe the working principle of an electromagnetic contactor.

Electromagnetic contactors generally consist of electromagnetic mechanism, contacts, arc extinguishing device, release spring mechanism, bracket and base. The contactor works according to the electromagnetic principle: when the electromagnetic coil is energized, the coil current generates a magnetic field, causing the static iron core to generate electromagnetic attraction to attract the armature, and drive the contact action, causing the normally closed contact to open and the normally open contact to close. The two are Linked. When the coil is powered off, the electromagnetic force disappears, and the armature is lowered under the action of the release spring to restore the contacts, that is, the normally open contact is opened and the normally closed contact is closed.

14. Briefly describe the definition of programmable controller (PLC).

A programmable controller (PLC) is an electronic device that performs digital operations and is specially designed for use in industrial environments. It uses a programmable memory to store instructions for performing operations such as logical operations, sequential operations, timing, counting, and arithmetic operations, and can control various types of controls through digital or analog inputs and outputs. Machinery or production process.

PLC and its related peripheral equipment should be designed according to the principle of being easy to form an integral whole with the industrial control system and easy to expand its functions.

15. Brief answer on the difference between the working principles of PLC system and relay contactor system.

The components are different;

The number of contacts varies;

Methods of implementing controls vary;

The way of working is different.

16. Brief answer: What are the characteristics of the STL step ladder instructions of Mitsubishi FX 2N series PLC?

(1) The transfer source is automatically reset;

(2) Allow dual output;

(3) Main control function.

How Hot Does a Pellet Mill Get?

Demystifying the Cone Crusher Machine: Your Guide to Understanding its Function and Benefits

Features of Gloves Counting Machine

Hollow Core Slab Machine: A Game Changer in Construction?

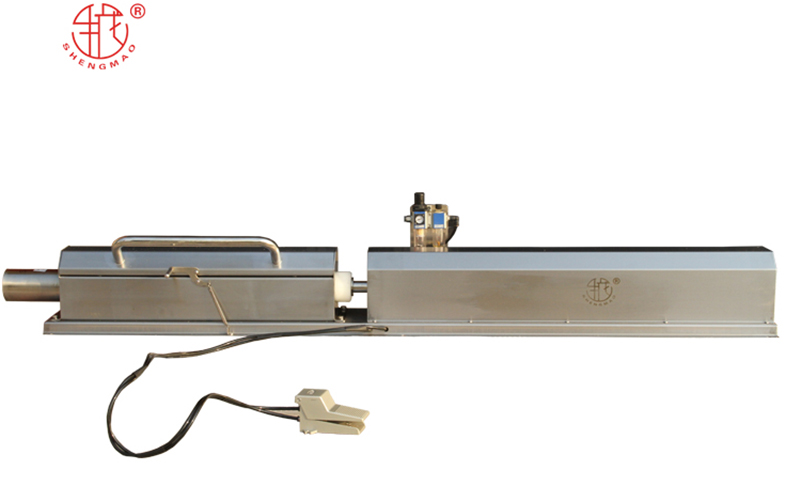

Advantages and Applications of CNC Gang Tool Lathes

Chicken Feed Pellet Machine

What is the meaning of ISO tank container?