Advantages and Features of Battery Crushing and Recycling Equipment

In today's society, the use of lithium batteries is increasingly widespread, from electric vehicles to portable electronic devices. However, with the extensive use of lithium batteries, the disposal of used batteries has become a pressing issue. Battery crushing and recycling equipment offers a reliable solution with its outstanding advantages and features to address this problem.

High-Efficiency Crushing and Fine Sorting

Battery crushing and recycling equipment utilizes advanced crushing technology to quickly break down used lithium batteries into small particles. The equipment is also equipped with a fine sorting system that effectively separates the various components of lithium batteries, such as cathode materials, anode materials, and separators. This efficient crushing and sorting process not only enhances recycling efficiency but also ensures the quality of the recycled materials.

The precision of the sorting system is crucial for recovering valuable materials. Cathode materials, typically composed of lithium cobalt oxide or lithium iron phosphate, are meticulously separated from anode materials like graphite. The separator materials, often made of polyethylene or polypropylene, are also sorted out. This meticulous separation ensures that each component can be processed and reused effectively, minimizing waste and maximizing resource recovery.

Safe, Reliable, Eco-Friendly, and Energy-Saving

Safety is paramount when handling used lithium batteries. The battery crushing and recycling equipment incorporates multiple safety protection measures to ensure operational safety. Lithium batteries can be hazardous due to their chemical composition and potential for leakage or explosion. Therefore, the equipment is designed with robust safety features, including automated shut-offs, explosion-proof designs, and containment systems to handle any leaks or ruptures.

Additionally, the equipment is designed to be eco-friendly and energy-saving. By optimizing process flows and adopting advanced energy-saving technologies, the equipment reduces energy consumption and minimizes environmental impact. For instance, the use of closed-loop systems in the recycling process can capture and reuse energy, further lowering the overall energy footprint. The reduction in energy use not only cuts operational costs but also decreases greenhouse gas emissions, contributing to a greener recycling process.

Intelligent Control and Easy Operation

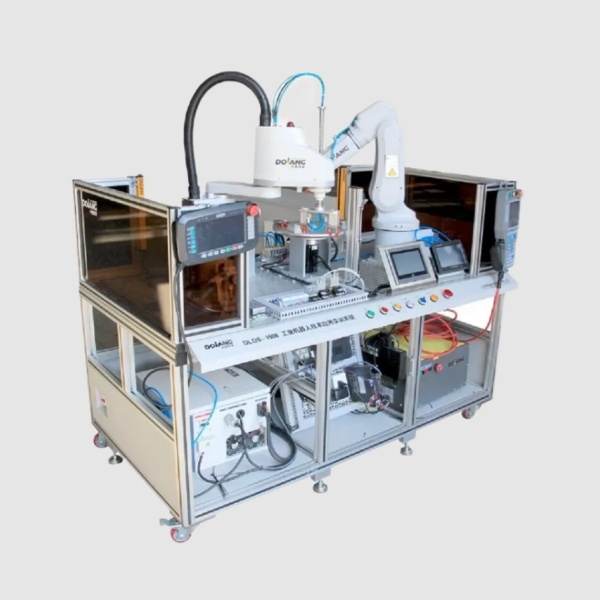

This equipment features an intelligent control system, enabling automated operation and remote monitoring. Operators can learn to use the equipment with minimal training. The intelligent control system not only improves production efficiency but also reduces labor costs and human error. Advanced sensors and real-time data monitoring allow for precise control over the recycling process, ensuring optimal performance and swift adjustments to any anomalies.

Bakery Bread Production Line: Manual vs. Automated Processes Explained

Choosing the Right Entry-Level Strapping Machine for Business

Top Soybean Oil Press Machines: Your Buying Guide Revealed!

Best Entry Level Rotary Heat Press for T-Shirts and Garments Reviewed

Mastering the Art of Manual Bun Dividers

What Benefits Do Zinc Electroplating Machines Offer Businesses?

Why Choose an Entry Level Rotary Heat Press with Large Platen Size?

The integration of artificial intelligence and machine learning in the control systems can further enhance efficiency. These technologies can predict maintenance needs, optimize sorting algorithms, and improve overall operational efficiency. With remote monitoring capabilities, operators can oversee the recycling process from anywhere, ensuring consistent performance and quick troubleshooting.

Customized Design to Meet Various Needs

Battery crushing and recycling equipment can be custom-designed to meet specific customer requirements. Whether it is processing capacity, sorting precision, or equipment size, adjustments can be made according to customer needs. This customized design better caters to different customer demands, providing personalized solutions.

For instance, facilities handling large volumes of batteries from electric vehicles might need equipment with higher processing capacities, whereas those dealing with consumer electronics might require finer sorting capabilities. Customizable features ensure that the equipment can adapt to the specific requirements of different industries, enhancing its versatility and effectiveness.

Addressing Environmental and Economic Challenges

The application of battery crushing and recycling equipment represents a significant advancement in addressing the challenges posed by used lithium batteries. The improper disposal of lithium batteries can lead to severe environmental issues, including soil and water contamination due to the leakage of hazardous materials. By recycling these batteries efficiently, we can mitigate these environmental risks and recover valuable materials that can be reused in new batteries or other products.

Economically, recycling lithium batteries reduces the need for raw materials, which are often costly and sourced through environmentally damaging mining practices. By recovering lithium, cobalt, nickel, and other materials from used batteries, we can create a more sustainable supply chain for battery production. This not only conserves natural resources but also stabilizes supply and reduces costs for manufacturers.

Conclusion

The adoption of advanced battery crushing and recycling equipment is crucial for promoting sustainable practices and reducing the environmental impact of lithium battery disposal. With its high-efficiency crushing and sorting capabilities, safety and environmental benefits, intelligent control, and customizable design, this equipment provides a comprehensive and effective solution for battery recycling. As the use of lithium batteries continues to grow, the implementation of such innovative recycling technologies will be essential in managing waste and conserving resources. This proactive approach not only addresses the immediate issue of battery disposal but also contributes to a circular economy where materials are continuously reused, reducing the overall environmental footprint.

Essential Commercial Bakery Equipment for Success

Exporting Pouch Lithium Battery Laser Welding Machines

Are Rising Costs Threatening the Future of Plating Operations in Saudi Arabia?

Ultimate Guide to Choosing the Best Oil Filtering Machine

How to Choose an Acrylic and Wood Laser Cutting Machine?

How to Choose a Private Label Battery Assembly Machine?

How Does pH Control Transform Plating Processes?