Comparing Pet Recycling Machines and Tire Shredder Machines

https://www.fangtaiplasticmachine.com/products/pe-recycling-machinery.html

In the realm of waste management and recycling, two prominent solutions stand out: pet recycling machines and tire shredder machines. Each serves a unique purpose in reducing environmental impact and promoting sustainability. In this comprehensive comparison, we delve into the pros and cons of both technologies to help you make an informed decision.

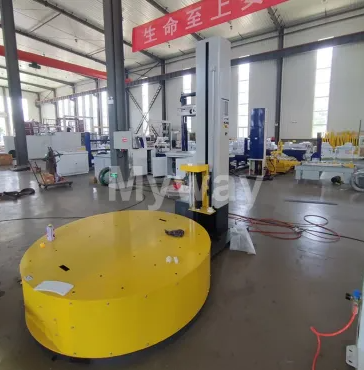

Pet Recycling Machines

Pet recycling machines are designed to process PET (polyethylene terephthalate) plastic, commonly used in beverage bottles and food packaging. Here are the key advantages and disadvantages of pet recycling machines:

Pros:

Environmental Sustainability: Pet recycling machines contribute to environmental conservation by reducing the amount of plastic waste in landfills and oceans. Recycling PET reduces the demand for virgin plastic, conserving natural resources.

Energy Efficiency: Recycling PET consumes less energy compared to producing new plastic from raw materials. Pet recycling machines facilitate the conversion of used PET into valuable raw material for manufacturing new products.

Versatility: These machines can process various forms of PET waste, including bottles, containers, and packaging materials. They offer flexibility in handling different types of plastic waste streams.

Cost Savings: Investing in a pet recycling machine can lead to long-term cost savings for businesses and municipalities. By recycling PET onsite, organizations can reduce waste management expenses and potentially generate revenue from selling recycled materials.

Cons:

Initial Investment: Acquiring a pet recycling machine involves a significant upfront investment. The cost of purchasing and installing the equipment may pose a barrier to entry for some organizations.

Maintenance Requirements: Pet recycling machines require regular maintenance to ensure optimal performance. Maintenance tasks may include cleaning, lubrication, and equipment calibration, adding to operational costs.

Space Requirements: Depending on the size and capacity of the machine, pet recycling equipment may require considerable floor space for installation. Limited space availability could be a constraint for smaller facilities.

Additional resources:What is the cost of automatic EPS shape molding machine?

How does a sand making machine work?

Can Bakelite be injection molded?

What is PCB etching machine?

Which Applications Benefit the Most from a Thermal Inkjet Printer for High-Quality Printing?

What Are The Applications of Electric Wheel Loaders?

Choosing the Right Tire Shredder Machine

Tire Shredder Machines

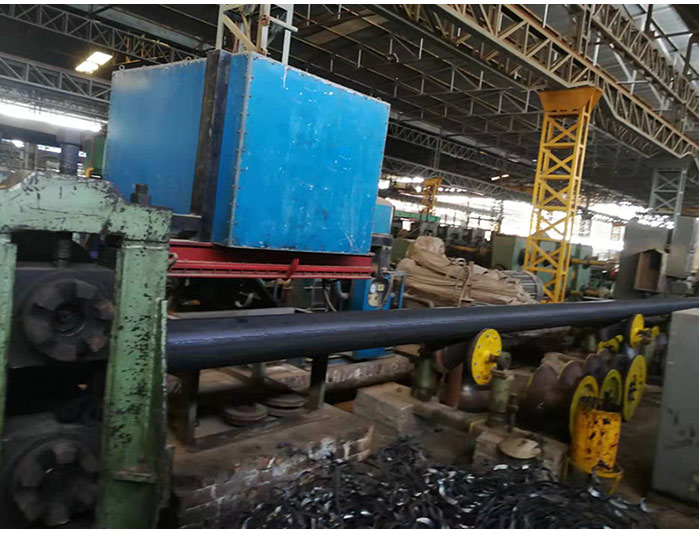

Tire shredder machines are specialized equipment designed to shred and recycle used tires, converting them into valuable resources. Let's explore the pros and cons of tire shredder machines:

Pros:

Resource Recovery: Tire shredder machines enable the recovery of valuable materials from used tires, such as rubber, steel, and textile fibers. These recycled materials can be used in various industries, including construction, automotive, and manufacturing.

Waste Reduction: By shredding and recycling used tires, these machines help mitigate the environmental impact of tire disposal. Recycling tires reduces the accumulation of waste in landfills and prevents harmful pollutants from leaching into the soil and water.

Energy Generation: In some cases, shredded tire material can be used as a fuel source for energy generation. Tires contain a high calorific value, making them suitable for incineration in waste-to-energy facilities.

Product Diversity: Tire shredder machines can produce a range of recycled products, including tire-derived aggregate (TDA), rubber mulch, and crumb rubber. These products have various applications in landscaping, construction, and civil engineering projects.

Cons:

Equipment Complexity: Tire shredder machines are complex pieces of equipment that require skilled operators for safe and efficient operation. Training personnel to operate and maintain the machinery can be time-consuming and costly.

Environmental Concerns: While tire shredding reduces waste and promotes recycling, it can also pose environmental challenges. The process may release pollutants such as VOCs (volatile organic compounds) and particulate matter into the air if not properly controlled.

Storage and Handling: Handling and storing shredded tire material require careful consideration due to its bulkiness and potential fire hazards. Adequate storage space and fire prevention measures are essential to mitigate risks.

In conclusion, both pet recycling machines and tire shredder machines offer valuable solutions for waste management and recycling. The choice between the two depends on factors such as the type of waste generated, available resources, and operational requirements. By weighing the pros and cons outlined in this comparison, organizations can make informed decisions to enhance their sustainability efforts and reduce environmental impact.

What is a gravure printing machine?

What to Consider When Purchasing a Compressor?

Exploring the Four Types of Electrical Actuators

How to Use Wire Straighteners: A Comprehensive Guide

Mastering Material Handling: The Fork Positioner Advantage

Oil Resistant Conveyor Belt: Navigating the Challenges of Conveying in Oily Environments

Exploring the Power of DC TIG Welding Machines