How Do I Choose a Hydraulic Seal? Why Are Hydraulic Seals Important?

Hydraulic seals are critical components in various industrial and mechanical applications, ensuring the proper functioning of hydraulic systems. Understanding how to choose the right seal and their importance is essential for optimal performance and longevity. In this guide, we'll explore the factors to consider when selecting hydraulic seals and discuss their significance in hydraulic systems.

Importance of Hydraulic Seals

Hydraulic seals serve several essential functions within hydraulic systems:

Leak Prevention: Hydraulic seals create a barrier that prevents fluid from leaking out of the system, ensuring efficient operation and preventing contamination of the surrounding environment.

Fluid Containment: By containing hydraulic fluid within the system, seals maintain proper fluid pressure, allowing hydraulic machinery to operate smoothly and efficiently.

Component Protection: Seals protect sensitive hydraulic components, such as pistons, cylinders, and valves, from damage caused by friction, debris, and external elements.

Performance Optimization: Properly functioning seals contribute to the overall performance and reliability of hydraulic equipment, minimizing downtime and maintenance costs.

How to Choose a Hydraulic Seal

Identify Application Requirements: Consider the specific requirements of your hydraulic system, such as operating pressure, temperature range, fluid compatibility, and environmental conditions. This information will help narrow down the selection of suitable seal materials and designs.

Select the Right Material: Hydraulic seals are available in various materials, including rubber, polyurethane, and PTFE (Teflon). Choose a material that offers the necessary durability, chemical resistance, and temperature tolerance for your application.

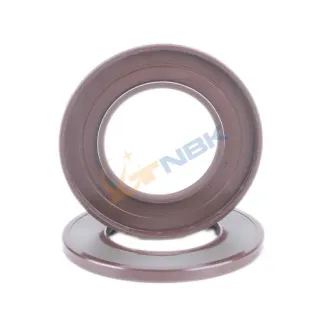

Consider Seal Design: Different seal designs, such as O-rings, lip seals, and rod seals, are suited to specific sealing applications. Determine the type of seal geometry and configuration that best matches your system requirements.

Size and Dimension: Ensure that the selected seal size and dimensions match the specifications of your hydraulic equipment. Proper sizing is crucial for achieving a secure and effective seal.

Additional resources:

Do O-rings have to be exact size?

Ultimate Guide to Understanding Floating Seal Technology

Can you use an airless sprayer without a filter?

Linear Dampers vs Axial Damper: Choosing the Right Solution

The Benefits of Using Activated Carbon Filters in Your Home

Drum Gear Coupling: The Backbone of Efficient Power Transmission

Selecting the Right Slurry Pump or Sand Dredge PumpEvaluate Performance Ratings: Pay attention to performance ratings such as pressure rating, speed rating, and temperature rating when choosing hydraulic seals. Select seals that can withstand the operating conditions of your hydraulic system without compromising performance or safety.

Quality and Reliability: Invest in high-quality seals from reputable manufacturers to ensure reliability and longevity. Quality seals are less prone to premature failure and can provide consistent performance over extended periods.

Consider Environmental Factors: Take into account any environmental factors that may affect seal performance, such as exposure to chemicals, UV radiation, or abrasive materials. Choose seals with suitable resistance to these elements to prevent degradation and premature wear.

Real-Life Applications of Hydraulic Seals

Hydraulic seals are used in a wide range of industrial and mechanical applications, including:

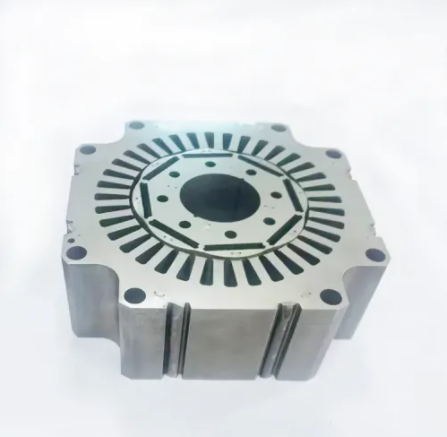

Construction Machinery: Hydraulic seals are found in hydraulic cylinders, excavators, bulldozers, and other construction equipment, where they help power hydraulic systems for lifting, digging, and maneuvering heavy loads.

Agricultural Equipment: Tractors, combines, and other agricultural machinery rely on hydraulic seals to operate hydraulic systems for tasks such as plowing, seeding, and harvesting.

Automotive Industry: Hydraulic seals are used in vehicle braking systems, suspension components, and power steering systems to maintain fluid pressure and ensure proper operation.

Manufacturing Machinery: Hydraulic presses, injection molding machines, and other manufacturing equipment utilize hydraulic seals to power hydraulic systems for shaping, cutting, and forming various materials.

Conclusion

Hydraulic seals are indispensable components in hydraulic systems, ensuring leak-free operation, fluid containment, and component protection. By understanding the factors involved in choosing the right hydraulic seal for your application and recognizing their importance in maintaining system performance, you can optimize the reliability and efficiency of your hydraulic equipment. Whether in construction, agriculture, automotive, or manufacturing industries, selecting quality hydraulic seals tailored to your specific requirements is crucial for achieving optimal results and minimizing downtime.

Benefits of Three Phase Hybrid Inverters

Factors to Consider Before Choosing an Overhead Block Clamp

What are Antigravity Motors?

The Power and Efficiency of Heavy Duty Slurry Pumps

Advantages and Applications of Butterfly Valves

How Does a Pallet Inverter Work?

Caterpillar Diesel Engine Models: Exploring the Range and Applications