Comparison of Performance Characteristics, Advantages and Disadvantages of Three Compressors

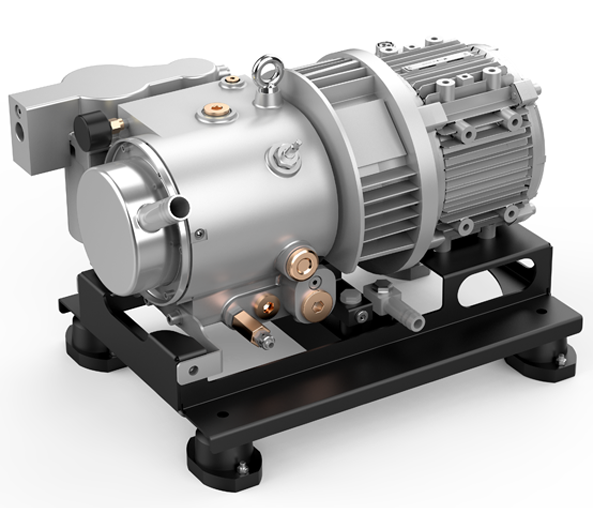

1. Screw compressor

Screw compressor is also called screw compressor. In the 1950s, oil-injected screw compressors were used in refrigeration devices. Due to their simple structure and few wearing parts, they can keep the exhaust temperature low under large pressure differences or pressure ratios, which is very important for refrigeration. The lubricant contains a large amount of lubricating oil (often called wet stroke), is not sensitive, and has good gas transmission volume adjustment. It quickly occupied the use range of large-capacity reciprocating compressors, and continued to extend to the medium-capacity range, widely It is widely used in refrigeration equipment such as refrigeration, refrigeration, air conditioning and chemical processes.

Screw heat pumps with it as the main engine have been used in heating and air conditioning since the early 1970s, including air heat source type, water heat pump type, heat recovery type, ice storage type, etc. In industry, in order to save energy, screw heat pumps are also used for heat recovery.

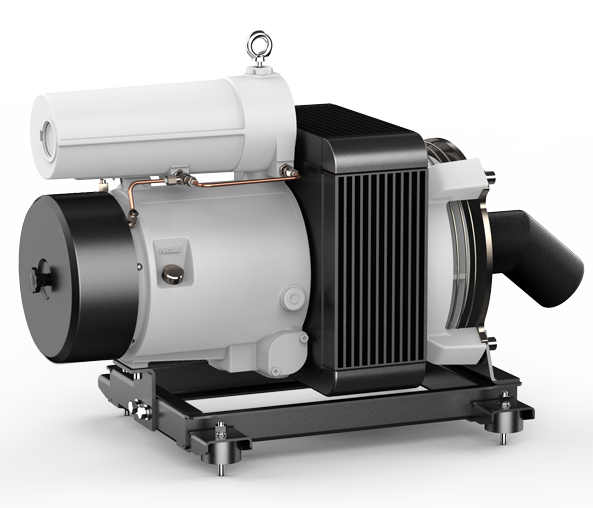

2. Centrifugal compressor

A centrifugal compressor is a rotary blade compressor (i.e. turbine compressor). In a centrifugal compressor, the high-speed rotating impeller gives the gas a centrifugal force and a diffusion channel to the gas, thereby increasing the gas pressure.

In the early days, because this kind of compressor was only suitable for low and medium pressure and large flow situations, it was not noticed by people. Due to the development of the chemical industry and the establishment of various large-scale chemical plants and refineries, centrifugal compressors have become a key machine for compressing and transporting various gases in chemical production, and occupy an extremely important position. With the achievements in gas dynamics research, the efficiency of centrifugal compressors has been continuously improved. Due to the successful development of key technologies such as high-pressure sealing, processing of small-flow narrow impellers, and multi-oil wedge bearings, the problem of centrifugal compressors moving towards high pressure and wide range has been solved. A series of problems in the development of flow range have greatly expanded the application range of centrifugal compressors, so that they can replace reciprocating compressors in many situations, greatly expanding the application range.

3. Reciprocating piston compressor

It is the earliest developed among all types of compressors. The wooden bellows invented in China in 1500 BC was the prototype of the reciprocating piston compressor. At the end of the 18th century, Britain made the first industrial reciprocating piston air compressor. Labyrinth compressors began to appear in the 1930s, followed by various oil-free lubricating compressors and diaphragm compressors. The counter-dynamic structure that appeared in the 1950s greatly reduced the size of large reciprocating piston compressors and enabled a single machine to be used for multiple purposes.

Piston compressors have a long history of use and are currently the most commonly used compressors in China. Due to its wide pressure range, it can adapt to a wide energy range. It has the advantages of high speed, multi-cylinder, adjustable energy, high thermal efficiency, and suitable for a variety of working conditions; its disadvantages are complex structure, many wearing parts, and short maintenance cycle. , sensitive to wet stroke, with pulse vibration and poor running stability.

Screw compressor is a new compression device. Compared with reciprocating type:

advantage:

①The machine has compact structure, small size, small floor space and light weight.

② Thermal efficiency is high and there are few machined parts. The total number of parts of the compressor is only 1/10 of that of the piston type. The machine has few wearing parts, safe and reliable operation, and simple operation and maintenance.

③ There is no pulsation in the gas and the operation is smooth. The unit does not need a special foundation because of its low foundation. ④ Oil is injected into the rotor cavity during operation, so the exhaust temperature is low.

⑤ Insensitive to wet strokes, wet steam or a small amount of liquid enters the machine, and there is no danger of liquid shock.

⑥Can operate under higher pressure ratio.

⑦The effective compression stroke can be changed with the help of the slide valve, and the cooling capacity can be adjusted steplessly from 10 to 100%.

shortcoming:

It requires complex oil treatment equipment, oil separators, oil coolers and other equipment with good separation effects. The noise is relatively large, generally above 85 decibels, and sound insulation measures are required.

Compared with the piston type, the centrifugal type has the advantages of high speed, large air volume, small mechanical wear, few wearing parts, simple maintenance, long continuous working time, small vibration, smooth operation, low basic requirements, and at large volume, the unit power The unit is light in weight, small in size, and occupies a small area. The gas volume can be adjusted steplessly within the range of 30% to 100%. It is easy to perform multi-stage compression and throttling. It can meet the requirements of certain chemical processes and is easy to realize automation. For Large machines can be directly driven by more economical industrial steam turbines, which has economic advantages for enterprises with waste heat steam. The disadvantages are: high noise frequency, large cooling water consumption, and surge when operated improperly.

Performance characteristics comparison of three common compression refrigeration machines (reciprocating, screw, centrifugal)

In the refrigeration system, because the working principles of reciprocating refrigeration compressors and screw refrigeration compressors are different, the causes of pressure loss and leakage loss that affect them are also different.

For reciprocating refrigeration compressors, the main factors affecting its pressure loss and leakage loss are the quality of the air valve and the sealing performance of the air valve when it is closed. This is because when the suction valve opens, it has to overcome the spring resistance (compression spring) and when the gas flows through the valve, due to the small passing cross section and high flow speed, a certain flow resistance is generated. Therefore, the reciprocating refrigeration compressor During the suction process, the pressure of the gas in the cylinder is always lower than the gas pressure in the suction pipe; similarly, during the exhaust process of the reciprocating refrigeration compressor, the pressure of the gas in the cylinder is always higher than the gas pressure in the suction pipe. If the passage section of the air valve is smaller, the resistance loss will be greater. If the weight of the valve plate is large and the spring force of the air valve is also large, the resistance loss will also increase, so the pressure coefficient value will decrease.

For screw refrigeration compressors, the main factor affecting its pressure loss and leakage loss is the gas flow rate.

In screw refrigeration compressors, the performance of the screw is key. If the tooth shape of the screw is a symmetrical arc shape, its manufacturing is simple. If the tooth shape of the screw is an asymmetric linear shape, then its air delivery screw volume will be large and the efficiency will be high. If the length-to-diameter ratio of the screw is reduced, the screw can have good strength, increase the reliability of the operation of the screw refrigeration compressor, and help the screw refrigeration compressor develop towards a high pressure ratio.

In a screw refrigeration compressor, there are two pairs of screws with the same diameter and length. The pair with a larger rotor area utilization coefficient has a larger exhaust volume. On the surface, the larger the rotor area utilization coefficient, the better the performance of the screw refrigeration compressor. However, if the rotor area utilization coefficient is too large, the strength and stiffness of the screw will be reduced.

In screw refrigeration compressors, reducing the number of screw teeth can increase the area between the screw teeth and increase the exhaust volume of the screw refrigeration compressor. On the surface, the fewer teeth the screw has, the better the performance of the screw refrigeration compressor. However, if the number of teeth of the screw is too few, the bending strength and stiffness of the screw will be reduced.

In a screw refrigeration compressor, increasing the peripheral speed of the screw can reduce the external size and mass of the screw refrigeration compressor, and the relative leakage of gas through the gaps in the screw refrigeration compressor will be reduced. , which is beneficial to improving the volumetric efficiency and thermal efficiency of the screw refrigeration compressor. On the surface, the faster the peripheral speed of the screw, the better the performance of the screw refrigeration compressor. However, if the screw circumferential speed is too fast, the flow loss of gas in the suction and exhaust orifices and the circumferential speed between teeth will correspondingly increase.

Among the three common refrigeration compressors (reciprocating, screw, and centrifugal), the inertia generated by the reciprocating motion is the main shortcoming of the reciprocating refrigeration compressor. Because they are often subjected to inertia caused by reciprocating motion, the valve and crank connecting rod mechanisms in reciprocating refrigeration compressors are most susceptible to damage.

Among the three common refrigeration compressors (reciprocating, screw, and centrifugal), the huge noise generated during operation is the main disadvantage of the screw refrigeration compressor. Because the refrigerant gas periodically passes through the suction and exhaust orifices at high speed, as well as leaks through gaps, a reasonable screw operating speed must be selected in a screw refrigeration compressor.

Among the three common refrigeration compressors (reciprocating, screw, and centrifugal), surge is the main disadvantage of centrifugal refrigeration compressors.

The reason for the surge of the centrifugal refrigeration compressor is that when the cooling water inlet volume of the condenser is reduced to a certain extent, the flow rate of the centrifugal refrigeration compressor is reduced to a very small level, and serious gas desorption occurs in its channel. flow, its outlet pressure suddenly drops. Although the centrifugal refrigeration compressor and the condenser work together, the pressure of the gas in the condenser does not decrease at the same time, so the pressure of the gas in the condenser is greater than the outlet pressure of the centrifugal refrigeration compressor, causing the condenser to The gas in the condenser flows back into the centrifugal refrigeration compressor until the gas pressure in the condenser drops to equal the outlet pressure of the centrifugal refrigeration compressor.

At this time, the centrifugal refrigeration compressor starts to supply air to the condenser again, the flow rate increases, and the centrifugal refrigeration compressor resumes normal operation. However, when the gas pressure in the condenser returns to the original gas pressure, the flow rate of the centrifugal refrigeration compressor decreases again, the outlet pressure of the centrifugal refrigeration compressor begins to drop, and the gas flows back again. This goes on and on, resulting in periodic airflow oscillations. Therefore, in a centrifugal refrigeration compressor, the cooling water volume of the condenser should not be too small, otherwise it will cause strong vibration when the centrifugal refrigeration compressor is running. In severe cases, it may even cause damage to the centrifugal refrigeration compressor. Destruction.

Summary:

In the refrigeration system, three common refrigeration compressors (reciprocating, screw, centrifugal) have different characteristics. Therefore, they have their own advantages and respective disadvantages in terms of performance.