Types of flexible packaging machines: A comprehensive guide

Flexible packaging machines are widely used in the packaging industry to package a variety of products using flexible materials such as plastic films, aluminum foils, and paper. In this comprehensive guide, we will explore the different types of flexible packaging machines available in the market, their features, and their applications.

Vertical Form-Fill-Seal (VFFS) Machines

Vertical form-fill-seal (VFFS) machines are one of the most commonly used types of flexible packaging machines. These machines operate vertically and are capable of handling a wide range of products, including dry powders, granules, snacks, liquids, and more. VFFS machines typically consist of a film roll holder, forming station, filling station, and sealing station.

The operation of VFFS machines involves forming a bag from a roll of film, filling it with the product, and then sealing it to create a finished package. The film roll holder holds the roll of film, which is pulled down to the forming station where the bag is formed. The filling station fills the bag with the product, and then the sealing station seals the bag, creating a tight and secure package.

VFFS machines come in different configurations, such as intermittent motion and continuous motion machines. Intermittent motion machines form and seal one bag at a time, making them suitable for slower production speeds. Continuous motion machines, on the other hand, form and seal bags continuously, making them suitable for higher production speeds. VFFS machines also offer various sealing options, including heat sealing, ultrasonic sealing, and impulse sealing, allowing for customization based on the specific packaging requirements.

Horizontal Form-Fill-Seal (HFFS) Machines

Horizontal form-fill-seal (HFFS) machines operate horizontally and are designed for products that are difficult to handle vertically or require a different orientation. HFFS machines typically consist of a film roll holder, forming station, filling station, and sealing station.

The operation of HFFS machines involves forming a flat, tubular bag from a roll of film, filling it with the product, and then sealing it to create a finished package. The film roll holder holds the roll of film, which is pulled across the forming station where the bag is formed. The filling station fills the bag with the product, and then the sealing station seals the bag, creating a tight and secure package.

Similar to VFFS machines, HFFS machines also come in different configurations, such as intermittent motion and continuous motion machines. Intermittent motion machines are suitable for slower production speeds, while continuous motion machines are suitable for higher production speeds. HFFS machines also offer various sealing options, including heat sealing, ultrasonic sealing, and impulse sealing, based on the specific packaging requirements.

Pouch Filling and Sealing Machines

Pouch filling and sealing machines are designed to fill and seal pre-made pouches. These pouches can be made from various materials such as plastic films, laminates, and paper, and come in different shapes and sizes, including stand-up pouches, flat pouches, and more. Pouch filling and sealing machines typically consist of a pouch feeding system, filling station, and sealing station.

The operation of pouch filling and sealing machines involves feeding pre-made pouches into the machine, filling them with the product, and then sealing them to create a finished package. The pouch feeding system feeds the pouches into the machine, and then the filling station fills the pouches with the product. Finally, the sealing station seals the pouches, creating a leak-proof and secure package.

Stick Pack Machines

Stick pack machines are designed to package products in narrow and elongated pouches called stick packs. These machines are suitable for packaging products such as sugar, coffee, salt,and other powders, granules, and liquids. Stick pack machines typically consist of a film roll holder, forming station, filling station, and sealing station.

The operation of stick pack machines involves forming a narrow and elongated pouch from a roll of film, filling it with the product, and then sealing it to create a finished stick pack. The film roll holder holds the roll of film, which is pulled across the forming station where the stick pack is formed. The filling station fills the stick pack with the product, and then the sealing station seals the stick pack, creating a slim and compact package.

Additional resources:Choosing the Perfect Double Shaft Paddle Mixer for Your Needs

How Does a Mobile Asphalt Plant Work?

The Differences Between Barrel and Rack Plating

The Benefits of Using Blow Molding Machines

What is the difference between a boom lift and a spider lift?

What is a cableway used for?

How much does a fiber laser cutter cost?

Stick pack machines can operate at high speeds, and their slim and compact design makes them suitable for products that require portion control or single-serve packaging. They also offer various sealing options, including heat sealing, ultrasonic sealing, and impulse sealing, depending on the specific packaging requirements.

Vacuum Packaging Machines

Vacuum packaging machines are designed to package products in an air-tight environment, removing the air from the package to extend the shelf life of the product. These machines are suitable for packaging products such as meat, fish, cheese, and other perishable items. Vacuum packaging machines typically consist of a vacuum chamber, sealing bar, and control system.

The operation of vacuum packaging machines involves placing the product inside a vacuum bag, which is then placed inside the vacuum chamber. The vacuum chamber removes the air from the package, creating a vacuum environment. The sealing bar then seals the vacuum bag, creating an air-tight package that extends the shelf life of the product.

Vacuum packaging machines can operate at different levels of vacuum, and they also offer various sealing options, including single seal and double seal options, based on the specific packaging requirements. They can also be combined with other packaging machines, such as filling machines, to create a complete packaging line.

Conclusion

Flexible packaging machines are essential for the packaging industry, allowing for the efficient and effective packaging of various products using flexible materials. Understanding the different types of flexible packaging machines available in the market, their features, and their applications can help businesses choose the right machine for their specific packaging needs. Whether it's a VFFS machine for dry powders, an HFFS machine for difficult-to-handle products, a pouch filling and sealing machine for pre-made pouches, a stick pack machine for slim and compact packaging, or a vacuum packaging machine for air-tight packaging, there is a flexible packaging machine suitable for every packaging requirement.

More articles:

Horizontal Flow Wrap Machine: Enhancing Packaging Efficiency and Productivity

What is a Roll Wrapping Machine used for?

How Do I Choose a Packing Machine?

How Are The Chips Packing Machine Working?

How to Choose Packaging Machinery Suitable for Your Business?

What are the advantages of fully automatic packaging machines?

What Are the Classifications of Packaging Machines?

Future Trends in the Wrapping Machine Industry: Unveiling Technological Marvels

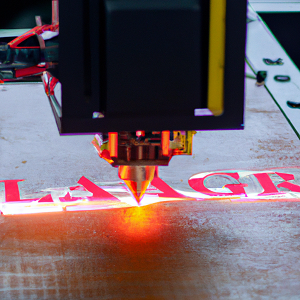

What is a fiber laser cutting machine used for?

What is a conveyor roller used for?

Do you really need a welding table?

Can I Use an Almond Grinder for Other Nuts? Exploring the Versatility of Nut Grinders

How does a golf ball making machine work?

Good Quality And Can Be Customized, Suncenter's High-flow Nitrogen Booster Equipment was Well Received

Can a Laser Cutter Effectively Cut Sheet Metal?