What Is a Double Lip Oil Seal and Its Benefits?

Double lip oil seals are vital for preventing leaks and protecting machinery components. This article explains their structure, benefits, and practical applications, helping you choose the right seal for your needs.

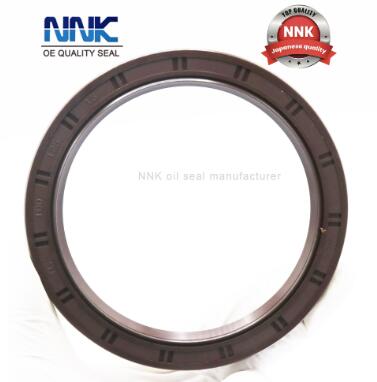

What Is a Double Lip Oil Seal?

A double lip oil seal is a mechanical component with two sealing edges designed to retain lubricants while blocking contaminants. It provides enhanced sealing performance in both static and dynamic applications.

How Does a Double Lip Oil Seal Work?

The primary lip retains oil within the system, while the secondary lip prevents dust, dirt, and moisture from entering. Combined, these lips ensure optimal performance and longevity for moving parts.

Key Features of Double Lip Oil Seals

| Feature | Description |

|---|---|

| Primary Lip | Seals lubricants to prevent leakage. |

| Secondary Lip | Blocks contaminants like dirt and moisture. |

| Spring Tension | Maintains consistent pressure for better sealing. |

| Durable Material | Resists wear, heat, and chemical exposure. |

Benefits of Double Lip Oil Seals

Enhanced Protection: Dual lips provide superior sealing against contaminants.

Extended Component Life: Prevents wear and tear on critical machinery parts.

Versatile Applications: Suitable for high-speed and heavy-duty environments.

Cost Efficiency: Reduces maintenance frequency and downtime.

Practical Example: Industrial Equipment

A manufacturing plant replaced single lip seals with double lip rubber oil seals in its conveyor systems. The upgrade reduced oil leaks by 40% and minimized equipment downtime, saving $15,000 annually in maintenance costs.

Common Applications of Double Lip Oil Seals

Automotive: Used in engines, transmissions, and axles.

Industrial Machinery: Protects bearings and shafts in heavy-duty equipment.

Agricultural Equipment: Ensures reliable performance in harsh outdoor environments.

Pumps and Valves: Prevents leakage in hydraulic systems.

FAQ

What materials are used in double lip oil seals?

Common materials include nitrile rubber, fluorocarbon, and silicone, chosen for their resistance to heat, chemicals, and wear.

How do I know if a double lip oil seal is needed?

If your application involves high contamination risk or requires extra sealing, double lip oil seals are ideal.

Can double lip oil seals handle high speeds?

Yes, they are designed for high-speed applications, especially in automotive and industrial settings.

How often should double lip oil seals be replaced?

Replacement intervals depend on application conditions but should follow manufacturer guidelines for optimal performance.

Conclusion

Double lip oil seals offer robust protection against leaks and contaminants, making them essential for various industries. Choose the right seal material and size to maximize efficiency and prolong equipment lifespan.