What is the Allowable Gap Between Flanges?

The allowable gap between flanges depends on several factors, including the type of flanges, the material they are made of, the pressure and temperature ratings of the flanges, and the specific application they are intended for. In general, the allowable gap between flanges is determined by the manufacturer's specifications or by industry standards and best practices.

Flanges are used in various applications, including pipe systems, pressure vessels, and other industrial equipment. They are designed to withstand pressure and provide a leak-free connection between components. The allowable gap between flanges is crucial for ensuring the structural integrity and safety of the system.

When selecting flanges for a specific application, it is important to consult the manufacturer's specifications or relevant industry standards. These documents will provide detailed information on the allowable gap between flanges for a given set of conditions.

Additional resources:How to Achieve Gear Coupling Reliability

How Reliable Are Caterpillar Diesel Engines?

What are the main three functions of a directional control valve in a hydraulic circuit?

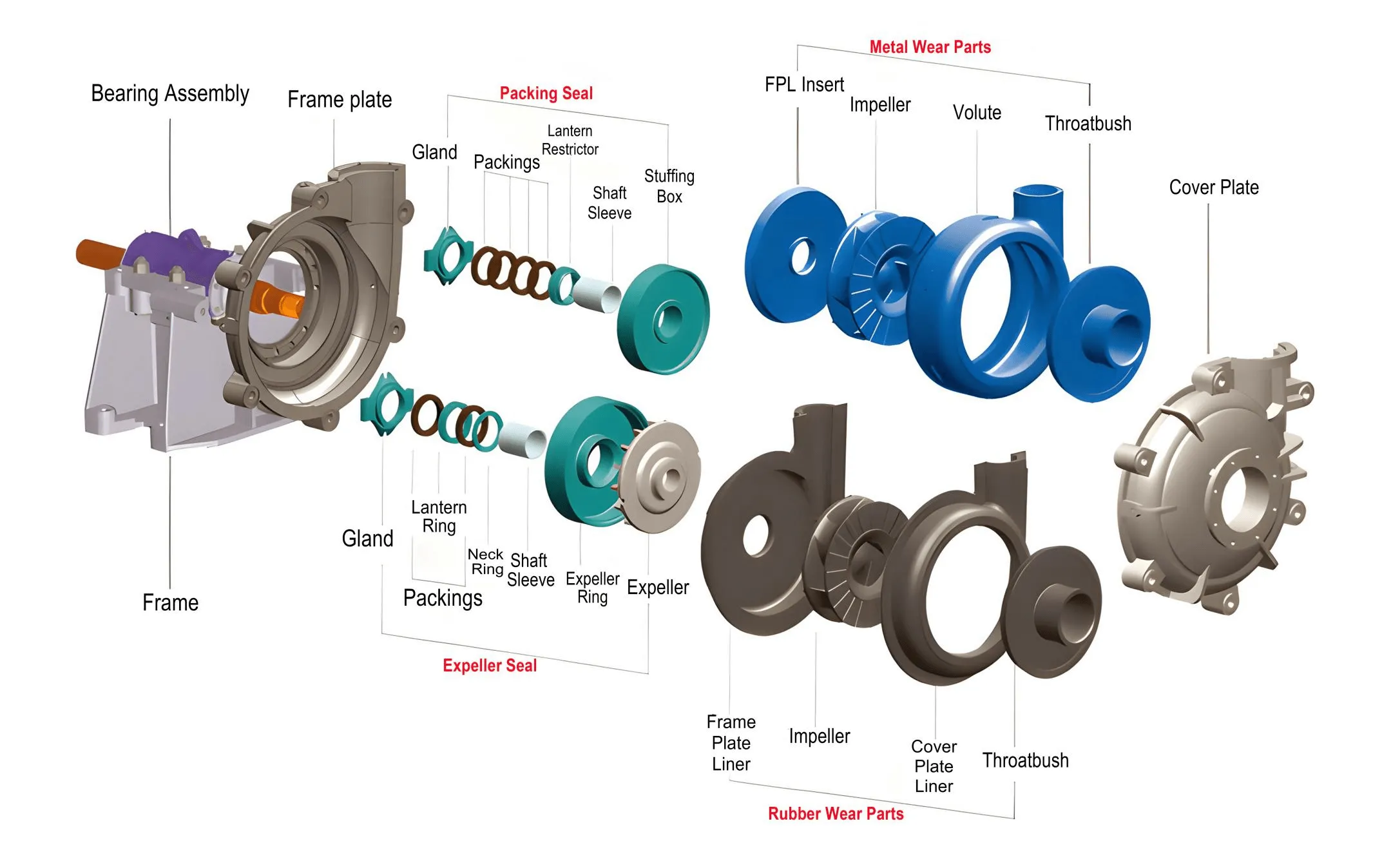

What is a Mechanical seal?

How to Choose the Right Sump Pump?

Understanding the Significance of Airless Spray Gun Filters

Exploring the Versatile Uses of Electronic Actuators

In addition to the manufacturer's specifications or industry standards, there are other factors that can affect the allowable gap between flanges. These include the operating conditions of the system, such as the temperature and pressure ranges, as well as the materials used for the flanges and any gasket material that is employed.

In general, a smaller allowable gap is preferred to ensure a tighter seal and greater structural integrity. However, it is important not to exceed the maximum allowable gap specified by the manufacturer or industry standards, as this can lead to leakage or even failure of the flanges.

In conclusion, the allowable gap between flanges depends on specific factors such as the type of flanges, materials, pressure and temperature ratings, and the application. It is essential to consult manufacturer's specifications or industry standards when selecting flanges to ensure that the allowable gap is appropriate for the intended use of the system.

The Power of Precision: Plane Thrust Ball Bearings

How Do Indexable Tools Keep Their Edge?

What is the stator in a DC motor?

How does a 1-inch diaphragm pump work?

What is precision surface finishing?

Are EVI DC Inverter Heat Pumps Suitable for Cold Climates?

What is an Off-Highway Vehicle Controller?